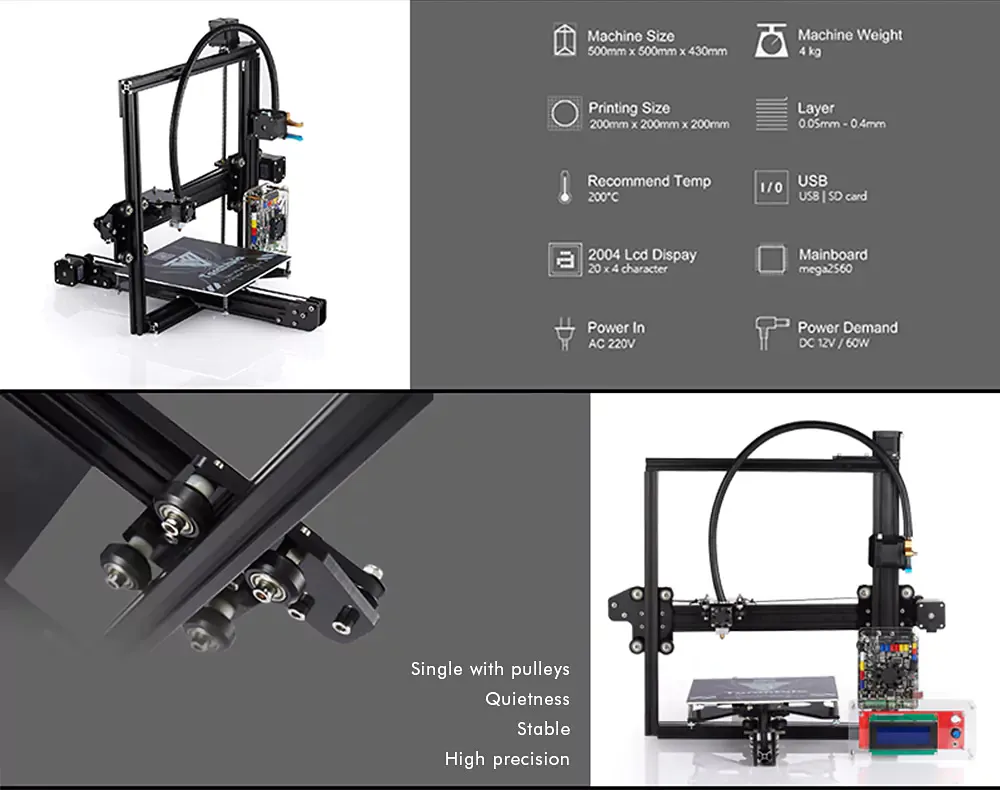

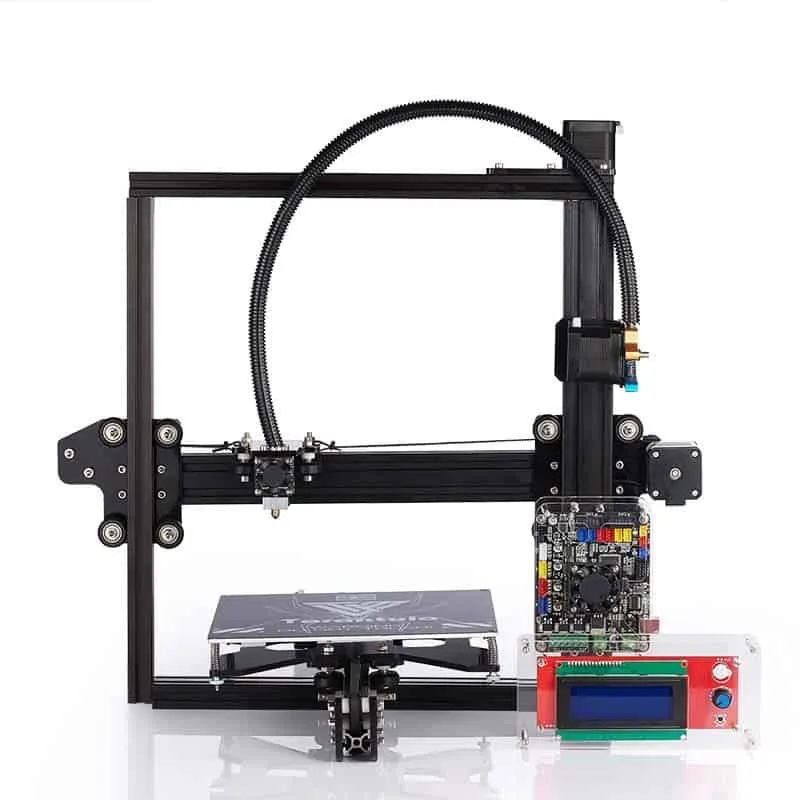

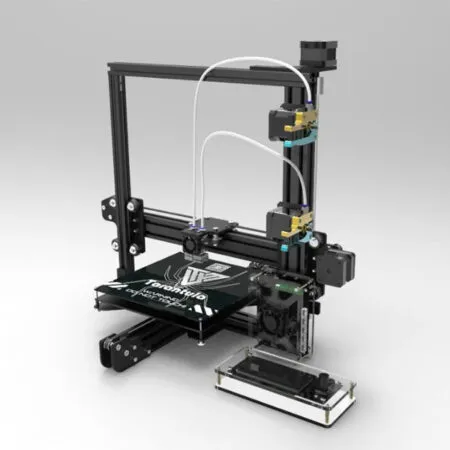

What is the Tevo Tarantula Carbon Fiber Kit

The Tevo Tarantula Carbon Fiber Kit is an upgrade designed to enhance the performance and aesthetics of the Tevo Tarantula 3D printer. This kit replaces the original frame components with carbon fiber parts, offering significant improvements in rigidity, stability, and overall print quality. This upgrade is popular among 3D printing enthusiasts looking to optimize their printer’s capabilities and achieve higher precision in their prints. The kit provides a cost-effective solution to improve your 3D printing experience without the need for a complete printer replacement. It’s a straightforward way to improve the performance of your existing 3D printer. The carbon fiber construction provides increased rigidity, which minimizes vibrations and improves print quality.

Benefits of the Tevo Tarantula Carbon Fiber Kit

Upgrading your Tevo Tarantula with a carbon fiber kit offers a multitude of advantages that can significantly enhance your 3D printing experience. The benefits extend beyond mere aesthetics, impacting print quality, printer stability, and overall longevity. By investing in this upgrade, you’re not just improving the look of your printer; you’re also investing in the quality and reliability of your 3D prints. The carbon fiber construction is a key factor to improve printer performance, providing a more stable platform for printing. It is a worthwhile investment for both beginners and experienced users looking to improve their 3D printing capabilities. The upgrade can lead to considerable improvements in print accuracy and the ability to handle a wider range of materials.

Improved Rigidity and Stability

Carbon fiber is renowned for its high strength-to-weight ratio, which translates into superior rigidity for your 3D printer’s frame. This increased rigidity minimizes vibrations during printing, which is a common cause of print defects like ghosting and ringing. A more stable frame ensures that the printer’s movements are precise and controlled, leading to smoother surfaces, sharper details, and overall higher quality prints. The enhanced stability also allows for faster print speeds without sacrificing accuracy, allowing you to complete projects more quickly. This stability is especially noticeable when printing at higher speeds, which can be critical for producing complex models and functional parts. This upgrade offers a significant improvement over the standard Tevo Tarantula frame, which can flex and vibrate during printing.

Enhanced Print Quality

The superior rigidity of the carbon fiber frame directly translates into improved print quality. By reducing vibrations and frame flex, the printer can maintain more accurate movements, resulting in cleaner lines, sharper corners, and more precise dimensional accuracy. This enhancement is particularly noticeable in intricate designs and overhangs. The carbon fiber upgrade helps to minimize common printing issues such as layer shifting and warping, which can ruin prints. You can also expect improved performance with flexible filaments and materials that are more prone to warping. The benefits of this enhancement extend beyond aesthetics, affecting the functionality of the prints.

Aesthetic Upgrade

Beyond its functional benefits, the carbon fiber kit significantly enhances the visual appeal of your Tevo Tarantula. The sleek, modern look of the carbon fiber components gives the printer a premium feel and makes it stand out. This aesthetic upgrade can be a great way to customize your printer and reflect your personal style. The carbon fiber finish adds a touch of sophistication that can be particularly appealing to enthusiasts who want their printers to look as good as they perform. This is a straightforward way to improve the aesthetics of your 3D printing setup. It’s a nice change from the standard look and can give your setup a professional appearance.

Tools and Materials Needed

Before you begin assembling the Tevo Tarantula Carbon Fiber Kit, it is essential to gather all the necessary tools and materials. This will ensure a smooth and efficient assembly process. Having everything prepared beforehand prevents interruptions and allows you to focus on the task at hand. It’s crucial to have all the necessary items available before starting the project, to prevent delays and make the assembly process easier. Proper preparation includes identifying and collecting the necessary tools, as well as reviewing the kit components and understanding their purpose. This will help in ensuring that the assembly process goes as planned. Prepare the workspace, ensuring it is well-lit and provides enough space for you to work comfortably.

Tools for Assembly

You will need a set of Allen wrenches (hex keys) in various sizes, commonly including 2mm, 2.5mm, and 3mm, as these are typically used for the screws in the printer frame. A Phillips head screwdriver is also necessary for various screws. A set of pliers may be useful for handling small parts and wires. A small adjustable wrench can be helpful for tightening nuts. It’s also good to have a utility knife or scissors for trimming any excess material or opening packaging. Consider having a digital caliper to verify dimensions and ensure accurate assembly. A set of needle-nose pliers is also useful for manipulating wires and small parts.

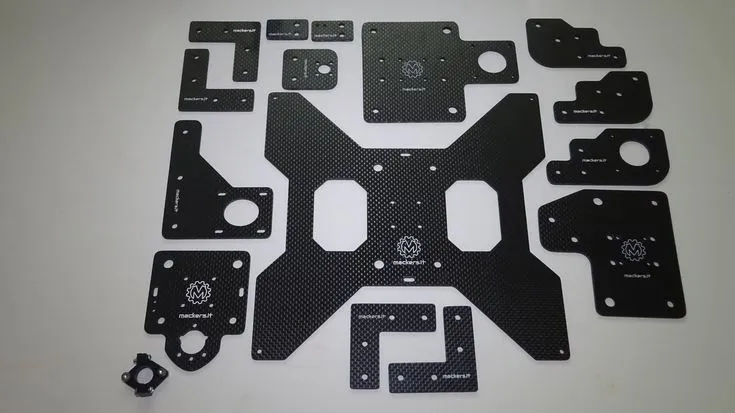

Carbon Fiber Kit Components

Carefully unpack the carbon fiber kit and identify all the components. The kit typically includes the carbon fiber frame pieces, which replace the original metal or acrylic frame parts. You’ll find various brackets, screws, nuts, and possibly other hardware necessary for assembly. Inspect all the parts for any damage and make sure everything is present. Ensure that you have all the necessary screws, nuts, and bolts for each component. Refer to the kit’s instruction manual to ensure that all components are identified, and organized for easy access during assembly. Make sure you have all the necessary components before you start the process. This will make sure you have all the required parts and avoid any unnecessary delays during the process.

Step-by-Step Assembly Guide

Follow this step-by-step guide to assemble your Tevo Tarantula Carbon Fiber Kit. It’s crucial to follow each step carefully to ensure the structural integrity and proper functioning of the printer. Taking your time and double-checking each step will minimize the risk of errors and ensure a successful outcome. Refer to the kit’s specific instructions for detailed guidance, as variations may exist between kits. The following steps provide a general overview of the assembly process.

Preparing the Tevo Tarantula

Begin by disconnecting the power to your Tevo Tarantula and removing any existing frame components. Carefully disassemble the original frame, keeping track of all screws and parts. Take photos of the original frame setup to help you with reassembly. Remove any existing brackets, supports, and other attached components. Clean the printer bed and other surfaces to ensure a smooth assembly. Before you start installing the new frame, make sure to remove any of the original frame parts. This will provide a clean base for the new carbon fiber components. This step ensures that all components are properly prepared before beginning the upgrade process.

Installing the Carbon Fiber Frame

Start by assembling the main frame components according to the kit’s instructions. Align the carbon fiber pieces and secure them with the provided screws and brackets. Ensure that the frame is square and properly aligned before tightening all screws. Use a level to verify that the frame is aligned correctly. Carefully attach the carbon fiber frame components to the base of the printer. This will provide a stable foundation for the rest of the assembly. Take your time and make sure that all components are aligned correctly, before tightening the screws.

Attaching the Z-Axis Supports

Install the Z-axis supports, ensuring they are aligned correctly to ensure smooth vertical movement. Attach the Z-axis stepper motors to the frame, and connect the Z-axis lead screws. Double-check the alignment of the Z-axis components to ensure they move freely without binding. Secure the Z-axis supports to the frame using the provided hardware, making sure everything is firmly tightened. Properly aligning and securing the Z-axis components is critical for ensuring smooth and accurate vertical movement. Make sure that the lead screws are properly installed and move smoothly through their supports.

Securing the X and Y Axis

Install the X and Y axis components, making sure they move smoothly along the rails. Attach the X and Y axis stepper motors, and connect the belts or leadscrews. Adjust the belts or leadscrews for proper tension. Ensure that the X and Y axes move smoothly and without any binding. Precise alignment and tensioning of the belts or leadscrews are crucial for print accuracy. Make sure the belts are properly tensioned to prevent slippage. Check that the print head can move freely and accurately across the print bed.

Wiring and Electronics

Carefully route and connect all the necessary wiring, including the stepper motor cables, endstop wires, and heated bed connections. Make sure to secure the wiring properly to prevent it from interfering with moving parts. Ensure that all connections are secure and properly insulated to prevent short circuits. Review the wiring diagram in your printer’s manual to ensure all connections are correct. Take care to route the wires in a neat and organized manner. This will prevent any interference with the printer’s functionality. Double-check all connections to make sure they are secure and properly insulated.

Connecting the Stepper Motors

Connect the stepper motor cables to the corresponding drivers on the control board. Double-check that the wiring is correct and that the motor drivers are properly configured. Refer to your printer’s manual for the correct wiring diagrams. Ensure that all connections are secure to prevent any motor malfunctions. Incorrect wiring can lead to significant issues. It is important to make sure that each stepper motor cable is correctly connected to its corresponding driver on the control board. Properly configured motor drivers are necessary for the smooth and accurate operation of your 3D printer.

Calibrating and Testing the Printer

After completing the assembly, it’s important to calibrate and test the printer to ensure everything functions correctly. Calibration ensures that the printer can print accurately, and testing helps you to identify and fix any potential issues. It is critical to ensure that the printer is printing accurately before you start printing complex models. Proper calibration will prevent print failures and ensure that you achieve the best possible results. Follow these steps to ensure your printer is properly calibrated and ready to print.

Leveling the Bed

Leveling the print bed is a critical step in ensuring that your prints adhere properly to the bed and that the first layer is laid down correctly. Use the leveling screws or auto-leveling features, if available, to ensure the distance between the nozzle and the bed is consistent across the entire surface. Make sure that the nozzle is the correct distance from the bed to ensure good adhesion. A properly leveled bed is key to successful printing. Accurate bed leveling ensures that the first layer of filament adheres correctly. A properly leveled bed reduces the risk of warping and poor print adhesion.

Testing the First Print

Once you have completed the assembly and calibration, it is time to test your printer with a simple test print. Select a test model that is suitable for assessing print quality and accuracy. Start with a small, simple object, such as a calibration cube. Monitor the print closely during the first few layers to ensure the filament is adhering correctly and that the printer is performing as expected. Check for any signs of warping, layer shifting, or other issues. Verify the dimensions of the printed object to check the accuracy of the prints. The first print will help you identify any adjustments needed to the printer settings or hardware. If the first print is successful, try a more complex model to further test the printer’s capabilities.

Troubleshooting Common Issues

Even with careful assembly and calibration, you may encounter issues. Here are some common problems and solutions. Knowing these troubleshooting steps can save you time and frustration. Problems can occur at any point during the process. It’s important to understand how to troubleshoot to identify the root cause of an issue. Knowing how to troubleshoot and solve these issues is important for successful 3D printing. By understanding the common problems, you will be able to minimize print failures.

Layer Shifting

Layer shifting is a common issue where the printed layers are misaligned. This can be caused by loose belts, binding on the axes, or incorrect motor current settings. Check the belt tension on the X and Y axes and tighten them if necessary. Ensure that the axes move smoothly and freely. Adjust the motor current settings to ensure that the motors have enough power. Regularly inspect and maintain your printer to prevent this problem. Properly tensioned belts and smooth axis movement will resolve the majority of layer shifting problems. Proper motor current will also make sure your motors operate correctly.

Nozzle Clogging

Nozzle clogging is a common issue that can stop printing. This can be caused by incorrect print settings, such as the temperature or the material being used. Increase the nozzle temperature slightly, and ensure you are using the correct filament type. Make sure that the filament is not contaminated. If the nozzle is severely clogged, you may need to disassemble and clean it, or replace it. Clean your nozzle frequently to keep it from clogging. You can use a needle to clear a clogged nozzle. You should also consider the material you are using as some filaments are more prone to clogging than others.

Conclusion

Upgrading your Tevo Tarantula with a carbon fiber kit is a rewarding project that can significantly enhance your 3D printing experience. By following the steps outlined in this guide, you can successfully assemble the kit and enjoy the benefits of a more rigid, stable, and aesthetically pleasing printer. Remember to take your time, double-check all connections, and calibrate your printer for optimal performance. With the carbon fiber kit installed, you can unlock the full potential of your Tevo Tarantula, achieving higher print quality, faster speeds, and greater reliability. Enjoy your upgraded Tevo Tarantula and happy printing!