Upgrading your Tevo Tarantula 3D printer with a dual Z-axis system is a significant improvement that enhances print quality and overall reliability. This comprehensive guide will walk you through every step of the installation process, from gathering components to calibrating your printer for optimal performance. With a dual Z-axis, you’ll experience smoother Z-axis movement, reduced binding, and greater stability, leading to more accurate and consistent 3D prints. This upgrade is a worthwhile investment for anyone looking to take their Tevo Tarantula to the next level. Get ready to unlock the full potential of your printer and achieve professional-grade results. Whether you are a beginner or an experienced maker, this guide provides all the information you need to succeed. Let’s dive in and transform your 3D printing experience.

Why Upgrade to a Dual Z Axis System?

The benefits of a dual Z-axis system are numerous, directly impacting the quality and ease of your 3D printing experience. By upgrading, you’re not just adding a component; you’re investing in a more reliable and efficient printing process. The dual Z-axis ensures that the print bed moves in perfect unison, eliminating common issues associated with a single Z-axis setup. This upgrade provides a solid foundation for achieving high-quality prints, reducing the need for constant adjustments and troubleshooting. The enhancements extend beyond the immediate print results, contributing to a more enjoyable and less frustrating 3D printing journey. The improvement in performance is noticeable, making the upgrade a valuable addition to any Tevo Tarantula setup.

Improved Print Quality

With a dual Z-axis, your prints will exhibit improved layer alignment and overall dimensional accuracy. The synchronized movement of the Z-axis motors ensures the print bed remains perfectly level throughout the printing process. This precision minimizes wobbling and inconsistencies, resulting in smoother surfaces and finer details. Fine lines, intricate designs, and complex geometries become easier to produce. The improved stability translates to a more refined and professional finish, providing a noticeable upgrade over prints produced on a single Z-axis system. You will be able to achieve more detailed and higher quality prints, allowing you to explore a wider range of creative projects.

Reduced Z-Axis Binding

Binding occurs when the Z-axis leadscrew experiences friction, causing uneven movement and layer shifting. The dual Z-axis setup eliminates this issue by distributing the load more evenly between two motors. This synchronized motion minimizes the chances of binding, allowing the print head to move smoothly along the Z-axis. By removing this source of inconsistency, the dual Z-axis system ensures that your printer operates at its peak performance. The enhanced smoothness translates directly into print quality, reducing the need for manual intervention and improving the overall reliability of your printing process. Say goodbye to frustrating layer shifts and hello to consistent, high-quality prints.

Increased Print Bed Stability

The dual Z-axis setup significantly increases the stability of the print bed. Two motors working in tandem provide more robust support, preventing the bed from tilting or wobbling during printing. This enhanced stability is especially crucial for larger prints or when using heavier materials. The added stability provides a more reliable base for the print, improving the chances of a successful print. This ensures that the print bed remains level, leading to more accurate and consistent results. This stability is a key factor in achieving high-quality prints, allowing you to confidently tackle complex projects. With this upgrade, your print bed will provide a more stable platform for all your 3D printing endeavors.

Gathering Your Tevo Tarantula Dual Z Axis Components

Before you begin the installation, ensure you have all the necessary components and tools. This includes the dual Z-axis kit, which typically consists of two stepper motors, lead screws, motor mounts, and associated hardware. Check the kit’s contents against the included parts list to avoid any surprises during installation. Having all components readily available will streamline the setup process and prevent unnecessary delays. It’s also wise to have a backup set of tools available to avoid downtime in case one breaks. Preparation is critical to a smooth and efficient upgrade process. A well-prepared workspace, stocked with all required components, will contribute to a more pleasant and successful installation experience.

Required Tools and Materials

In addition to the dual Z-axis kit, you’ll need specific tools and materials. Common tools include Allen wrenches (typically those that came with your Tevo Tarantula), a screwdriver set, a digital multimeter (for testing connections), and possibly a small level. You may also need zip ties or cable management solutions for tidying up the wiring. Verify that your tools are in good working order. Having all the necessary tools at your fingertips will greatly simplify the installation process. Ensure you have all necessary components before starting. Proper preparation is critical for a smooth and efficient upgrade. With the right tools, you’ll be well-equipped to complete the dual Z-axis upgrade successfully.

Purchasing the Dual Z Axis Kit

Dual Z-axis kits for the Tevo Tarantula are readily available from various online retailers. When selecting a kit, consider factors such as the quality of components, customer reviews, and the availability of installation instructions. Compare prices and features to find a kit that meets your needs and budget. Purchasing from a reputable supplier is crucial to ensure you receive high-quality components that function effectively. Carefully evaluate different kits, considering user feedback and technical specifications to make an informed decision. Make sure the kit is designed specifically for the Tevo Tarantula model. Choosing a well-regarded kit increases the likelihood of a successful upgrade and improved 3D printing results.

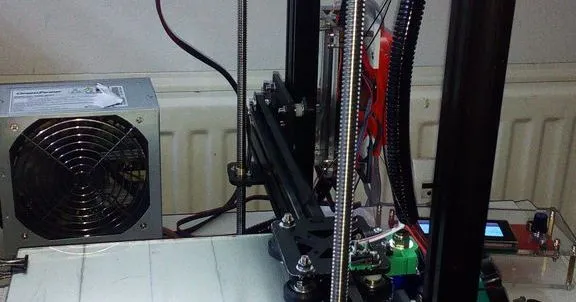

Step-by-Step Dual Z Axis Installation

With your tools and components ready, you can begin the installation. This step-by-step process will guide you through each stage, ensuring a smooth transition to a dual Z-axis system. It is recommended to work in a well-lit area, to avoid losing parts. Follow the instructions meticulously, paying close attention to detail. Take your time and double-check all connections and alignments. This approach minimizes the chances of encountering problems during and after the upgrade, guaranteeing a positive outcome. With careful attention to detail, your Tevo Tarantula will be running with its new and improved dual Z-axis system. Patience and precision are key to a successful installation.

Preparing the Tevo Tarantula Frame

Before installing the new components, prepare the frame of your Tevo Tarantula. This includes removing the existing Z-axis motor and lead screw. Take pictures of the original setup before disassembly for reference. Carefully detach the original Z-axis motor and leadscrew, ensuring to keep all screws and hardware organized. This preparation clears the way for the new dual Z-axis system. Double-check your work against the original setup and make sure everything is correctly placed. The goal is to create a clean slate for the new upgrade, making the installation of the dual Z-axis system simpler and more effective. This preliminary step streamlines the upgrade process, reducing the risk of complications later on.

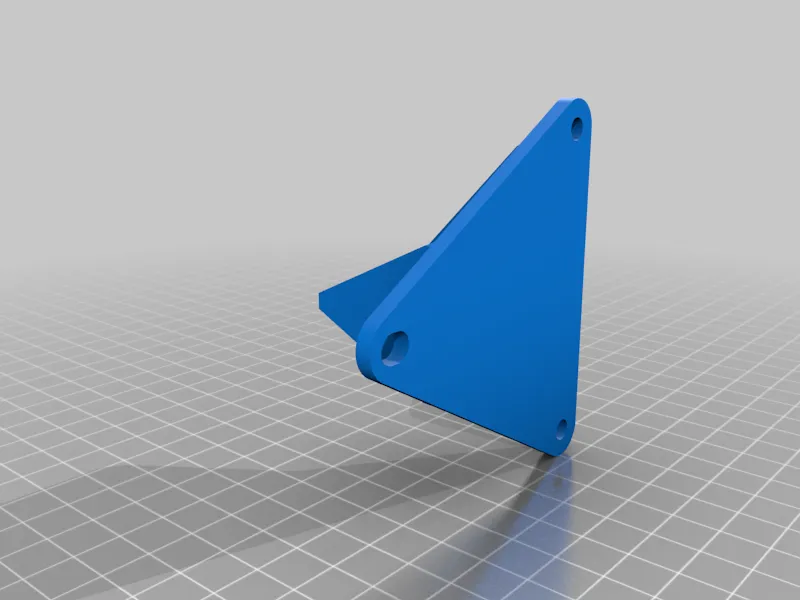

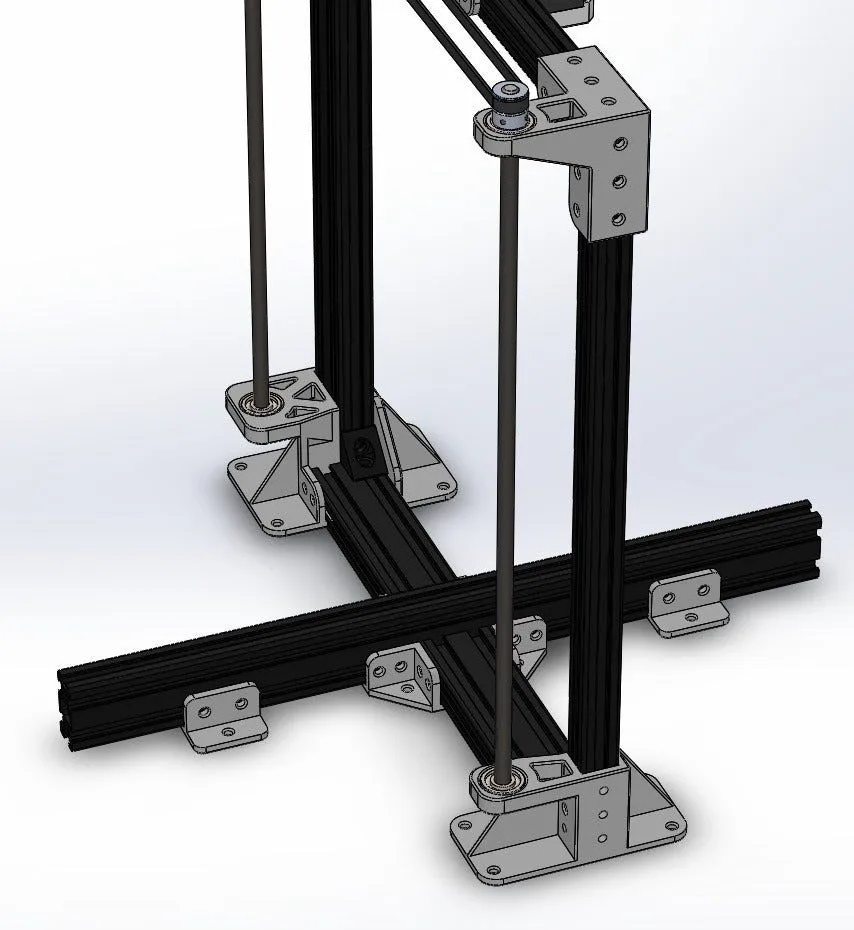

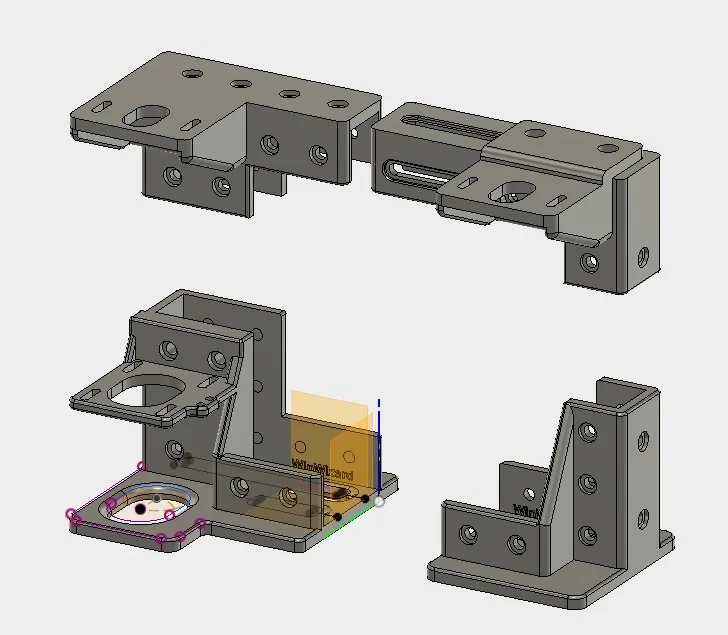

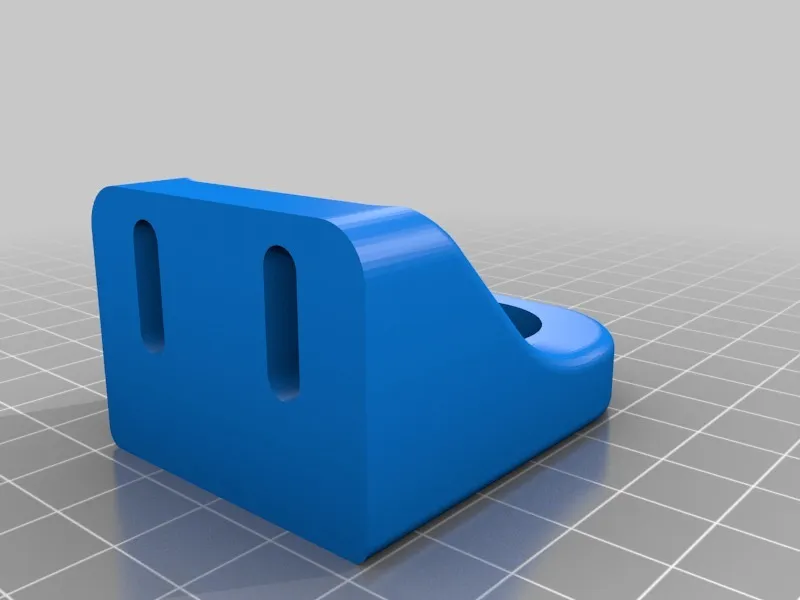

Mounting the Z-Axis Motors

Carefully mount the new Z-axis motors onto the frame. The kit should include specific brackets or mounts for these motors. Ensure the motors are securely attached and aligned properly. Tighten all screws firmly. Check the motor orientation to ensure they are positioned correctly. This step is crucial for the proper functioning of the dual Z-axis system. Secure and aligned motor mounting will eliminate potential printing problems down the line. Using a level, ensure that the motor mounts are perfectly aligned. Properly mounted motors are essential for a stable and reliable dual Z-axis system. Double-check all connections, and ensure that all screws are properly tightened.

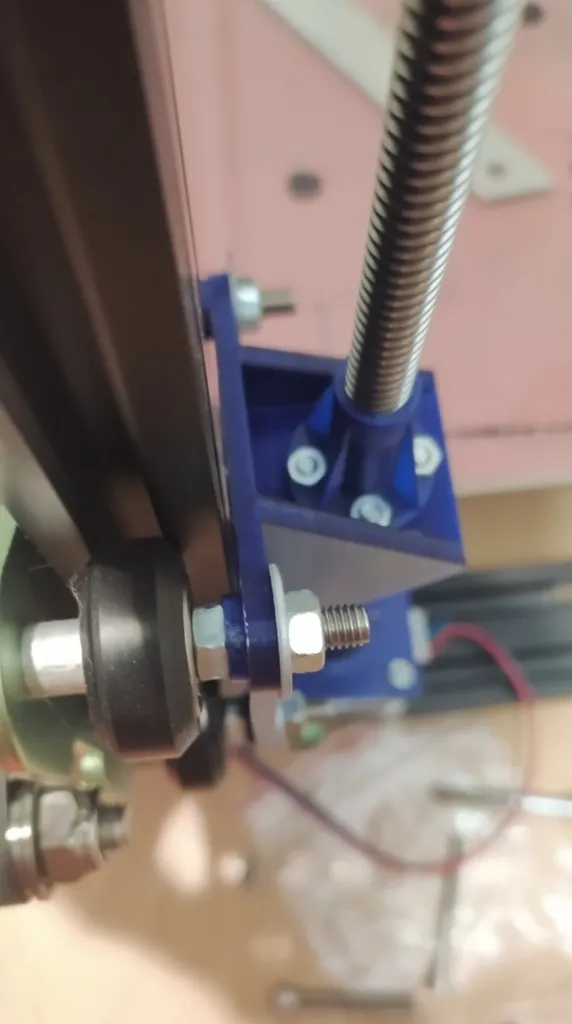

Connecting the Lead Screws

Attach the lead screws to the Z-axis motors. Most kits provide couplers to connect the lead screws directly to the motor shafts. Ensure the couplers are properly secured to prevent slippage. It is critical that the lead screws are aligned correctly. Make sure the lead screws are straight and aligned with the Z-axis carriages. Precise lead screw attachment is essential for consistent Z-axis movement. This is one of the most crucial aspects of the installation, affecting print quality. Proper alignment and secure connections are key to ensuring that the print bed moves smoothly and evenly during printing. Take extra care during this stage to avoid future issues.

Installing the Z-Axis Limit Switches

Install the Z-axis limit switches. These switches are essential for homing the Z-axis and ensuring the print bed starts at the correct height. Mount the limit switches in their designated positions and connect them to the control board. Proper placement and wiring of the limit switches are crucial for accurate homing and safe operation. Make sure the limit switches are triggered at the correct position. Careful wiring prevents short circuits and ensures reliable performance. Double-check your wiring connections. This is a vital part of the system, providing crucial information to the printer’s firmware.

Wiring the Motors and Limit Switches

Connect the motors and limit switches to the control board. Refer to your printer’s manual or the dual Z-axis kit instructions for the correct wiring diagrams. Ensure all connections are secure and properly insulated. Double-check the wiring to avoid any shorts or incorrect connections. Using zip ties or cable management solutions can help keep the wiring tidy. Correct wiring is critical for safe and reliable printer operation. Taking your time during this phase can prevent operational issues. Ensure that all the wires are properly connected and secured. Properly wired motors and switches are essential for the functioning of the upgraded system.

Configuring the Firmware

After the hardware installation, you need to configure your printer’s firmware. You will need to update the firmware to accommodate the dual Z-axis setup. This involves adjusting the motor driver settings and potentially modifying the Z-axis travel limits. You can generally do this with a computer and an Arduino IDE setup, or through the printer’s onboard menu. Make sure you back up your original firmware before making any changes. Refer to your printer’s firmware documentation and the dual Z-axis kit instructions for specific settings. This is a crucial step in ensuring the printer recognizes and controls the dual Z-axis properly. The correct firmware settings are necessary for the printer to operate effectively. This will help make the dual Z-axis run correctly and efficiently.

Adjusting Stepper Motor Drivers

Adjusting the stepper motor drivers is necessary to ensure optimal motor performance. You may need to adjust the voltage on the stepper motor drivers to match the specifications of your motors. Use a multimeter to measure the voltage and make any necessary adjustments. Consult your printer’s manual for guidance on adjusting the stepper motor drivers. Ensure that the motors are receiving the correct amount of power. This step will affect the motor’s performance. Properly calibrated stepper motor drivers are essential for precise and reliable Z-axis movement. Incorrect voltage can result in motor overheating or underperformance.

Calibrating the Z-Axis

Once the firmware and hardware are in place, it’s time to calibrate the Z-axis. This involves ensuring the print bed moves smoothly and evenly. You may need to adjust the lead screws to eliminate any wobble. The print bed should be perfectly parallel with the X-axis. Verify the Z-axis movement and make any necessary adjustments. Calibration is a critical step for achieving accurate and consistent prints. Carefully check the movement of both Z-axis motors to ensure they are moving in sync. Proper calibration is essential for ensuring accurate print heights and layer alignment. This guarantees the bed is level across the entire surface.

Leveling the Print Bed

Bed leveling is critical for successful 3D printing. With the dual Z-axis installed, bed leveling becomes more straightforward. Use the leveling screws to ensure the print bed is perfectly level. Utilize a level or a piece of paper to test the height at different points on the bed. You can also use the auto-leveling feature, if available. Precise leveling ensures that the first layer adheres correctly. Leveling ensures that the initial layers of your print adhere properly and prevents warping or other print defects. Regularly checking and adjusting the level ensures optimal print quality. Spend sufficient time on leveling to achieve a perfect first layer.

Testing and Troubleshooting

After completing the installation and calibration, it’s time to test your new dual Z-axis system. Conduct some initial tests and troubleshoot any issues that may arise. Testing ensures that all components are functioning correctly and identifies potential problems before you start printing complex models. Pay close attention to the Z-axis movement and the print bed leveling. Troubleshooting is a normal part of the process. It’s important to have patience and try different solutions. This phase is essential to making sure all components are properly working, which will ultimately result in prints of higher quality. Regular testing and maintenance will ensure the ongoing optimal performance of your upgraded 3D printer.

Initial Print Test

Start with a simple print test, such as a calibration cube or a small model. This will help you assess the print quality and identify any potential issues. Observe the first few layers closely, paying attention to the layer adhesion and overall print accuracy. If possible, use a pre-made calibration print to help diagnose any potential problems. The test print is critical for verifying all your setup steps. If the test print exhibits imperfections, it will help you to locate those problems before printing larger models. This preliminary test will quickly identify any necessary adjustments. Always start with a small test print to verify the success of the upgrade.

Troubleshooting Common Issues

Common issues include layer shifting, Z-axis binding, and bed leveling problems. Layer shifting can occur if the motors are not properly calibrated or if the belts are too loose. Z-axis binding might occur if the lead screws are not aligned correctly or if the motors are not powerful enough. Bed leveling problems can cause poor first-layer adhesion and warping. Consult online forums, and user manuals for troubleshooting tips. Taking the time to research these common issues will help you troubleshoot issues effectively. If you encounter issues, don’t be discouraged. Troubleshooting is a part of the 3D printing experience. By carefully following these troubleshooting steps, you can resolve common issues and get your printer working perfectly.

Upgrading your Tevo Tarantula with a dual Z-axis system is a rewarding project that significantly enhances your 3D printing experience. By following this guide, you can improve your print quality, reduce printing defects, and increase overall printer reliability. With the dual Z-axis, you will see a marked improvement in the quality of your prints. With a dual Z-axis installed, your Tevo Tarantula 3D printer will be capable of producing higher-quality prints with increased stability and precision. Embrace this upgrade and unlock the full potential of your 3D printer, allowing you to bring your creative visions to life with greater accuracy and ease. Enjoy the journey of continuous improvement in the world of 3D printing.